SEJ is the simplest metal expansion joint, of single bellows element make out from either a single plies or multiplies constructions using both side Weld Ends, Flanges or One side Weld Ends other side Flanges assembly unit. Its can absorb axial movement from the pipe lines, duct and vibration from the equipment. All the SEJ needs fix anchor and intermediate anchor for smoothly work in the process.

Dual Expansion Joint ( DEJ )

The DEJ is consists of two SEJ by common pipe/duct connector for the purpose of absorbing any combination of three basic movement, axial expansion and compression, lateral deflection and angular rotation.

Hinge Expansion Joint ( Single OR Dual )

The HEJ is contains Single or Dual Expansion Joint and its can design to permit angular rotation and if UEJ than lateral movement in One plane only by using a pair of pins through hinge plate and its fix with end connection of expansion joint assembly. All the hinge pins and plate are design to restrain the thrust force due to internal pressure and extraneous force, wherever applicable. As per below photos.

Tied Expansion Joint ( Single OR Dual )

The TEJ is contains Single or Dual Expansion Joint and its can design to permit axial, lateral(One plane or Two plane) and angular movement. The devices called tie rods or bars, attached with end connection of expansion joint assembly whose primary function is to distribute the equal movement between the single or deal bellows, restrain the trust force during internal pressure.

Gimbal Expansion Joint ( Single OR Dual )

The GEJ is design to permit angular motion in all planes. The incorporation includes a pair of hinges connected to a floating Gimbals ring which has very special advantages to absorb thrust force due to internal pressure, supporting the dead weight of the system, prevention of torsion force & reduction of forces on system.

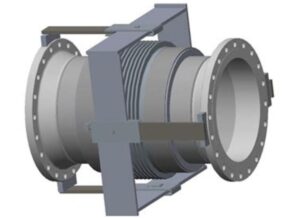

Pressure Balance Expansion Joint

The PBEJ is design in single or Dual Expansion Joint and its can absorb axial and lateral movement. Single or Double line bellows assembly connected with the balancing bellows using devices call tie rods or bars to restraining the axial and compressive thrust force due to internal pressure and its can allow free to move for lateral movement. Also supporting the dead weight of the balancing bellows and blind flange or dished ends. Each bellows set is designed to absorb the axial movement and usually the line bellows absorb lateral deflection.

In-line Pressure Balance Expansion Joint

The IPBEJ is design in a two type of construction, either using a Tie rods or using a connected spool piece with line bellows and balancing bellows. Its can absorb large axial movement and minor lateral movement. This type of the expansion joint is design only for a straight run of pipe, where axial movements are large.

Externally Pressurized Expansion Joint

The EPEJ is design for absorb a large axial movement and minor lateral movement. This type of the expansion joint is design only for a straight run of pipe, using shoes type fix support on the bottom side of outer shell to divide the equally moment on both bellows element if dual bellows design.

Externally Pressurized Expansion Joint

The EPEJ is design for absorb a large axial movement and minor lateral movement. This type of the expansion joint is design only for a straight run of pipe, using shoes type fix support on the bottom side of outer shell to divide the equally moment on both bellows element if dual bellows design.

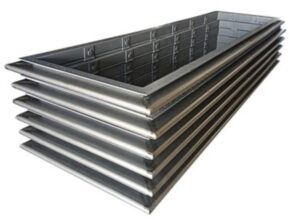

Metallic Rectangular or Squire Expansion Joints

Square and Rectangular Bellows: Any size with any shape and corner Rectangular Bellows especially used in low pressure ducting to absorb thermal expansion of duct and vibration from equipment. Rectangular Expansion Joint have a single, miter, camera and rounded corner design to absorb axial and lateral movement due to thermal expansion of system.

Metallic Thick Wall and Cold Spun Expansion Joints

Thick wall Expansion Joint especially design for Heat Exchanger application. Due to dissimilar material, pressure or temperature of shell side and tube side there are differential thermal growth between shell and tube, to absorb this thermal growth or expansion, need the expansion joint. This expansion joint design as per ASME Code – Div VIII – Appendix 5 or 26 and TEMA – Section – V RCB – 8.

Non Metallic Fabric Expansion Joints

These are used when large movement over a relatively short installation is required. Their use in large ducting system in place of metallic expansion joints reduce cost and weight, enabling fast and simple replacement at the same time.

Indiaflex manufactures and supplies a wide range of sizes and applications with or without frames. These frames can be designed to suit your application in carbon steel or stainless steel.

We can supply this with either CS or SS steel work, refractory or no refractory as required by the customer

Non Metallic Composite Type Expansion Joints

This is made up of inner layer, insulation layer pressure seal and outer layer. There is an insulation pillow for high temperature application. This comes with different coating to suit the medium and the environment.

Non Metallic Elastomeric Type Expansion Joints

This comes as a single layer of Hypalon, EPDM, Vitron, Teflon and combination of Viton and Teflon. We follow this latest International trend due to its effective and durable solution of handling low to medium temperature gasses, associated dew point condensate and flue gas.

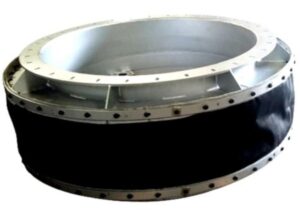

Non Metallic Rubber Expansion Joints

These expansion joints are often used in water and chemical applications where lateral movement, misalignment or vibration is evident in the piping system. Our rubber expansion joints come in single and double spherical style arch type in EPDM, Neoprene, Nitrile, Hypalon Viton & Teflon lined.